Anthony Rossi begins by buying oranges from supermarkets and turning them into citrus gift boxes.

Late 1940s

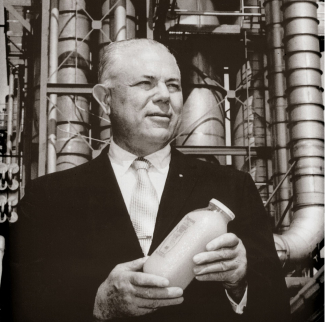

Company pioneers flash pasteurisation, an innovative method that raises the temperature of freshly squeezed orange juice quickly, extending the juice’s shelf life while maintaining its flavour

1957

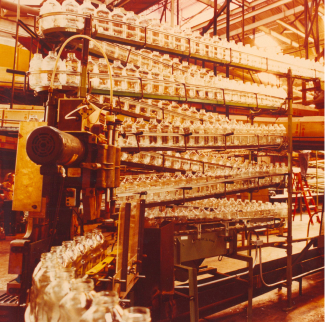

Tropicana begins manufacturing its own bottles, making it faster and easier to produce juice.

1965

Tropicana’s Great White Train (eventually painted orange) makes its inaugural run to the Northeast, USA.

1989

Tropicana launched in the UK and ROI.

1995

Tropicana becomes part of PepsiCo, a move that unites the world's second-biggest beverage company with the largest producer of branded juices.

2000’s

Tropicana Brands Group is established as a joint venture between PAI Partners and PepsiCo.

Tropicana celebrates 75 years of making orange juice.

2023

Early

1940s

Rossi develops a first-of-its-kind process to ship citrus fruits to the masses in glass containers.

1954

Steamship Tropicana takes off, delivering 1.5M gallons of orange juice from Florida to New York every week.

1964

Tropicana receives its first international order for 13,000 cases of Tropicana orange juice at the European Food Industry Trade Fair.

1970

Tropicana introduces the iconic red and white straw in a commercial touting the pureness of the orange juice.

1991

Tropicana facilities can process 1.7M gallons (2M bottles) of juice daily.

1998

Tropicana introduces a diverse array of innovative juices, from lower-sugar juices to whole fruits and Tropicana Plus, all of which have contributed to building our successful and trusted brand, making it the most loved juice in the UK.

2022

TBG continues the Tropicana spirit of innovation, launching ambient long life and kids juices, and introducing the ‘It’s THAT Juice’ creative platform, marking a triumphant comeback to the market.